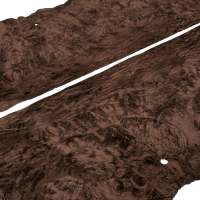

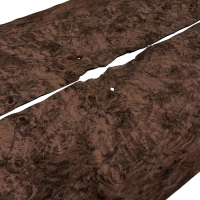

Walnut Burl Veneers 130 x 34 cm

Walnut Burl Veneers 130 x 34 cm

Genuine wood sliced-veneer sheets, in sequence.

Length: 130 cm.

Width: 34 cm.

Thickness: 0.55 mm.

Sold by the sheet.

These photos are taken from the veneer sheets you will receive.

Walnut Burl Veneers 130 x 34 cm

Genuine wood sliced-veneer sheets, in sequence.

Dimensions:

Length: 130 cm.

Width: 34 cm.

Thickness: 0.55 mm.

Measurement scaling:

The length and the width is rounded to the covered centimeter. For example, 15.8 cm is given 15 cm.

Pictures:

These photos are taken from the veneer sheets you will receive.

While we strive to capture the color as accurately as possible, please note that the color may vary slightly from the photo. The screen on which the photos are viewed can also affect their appearance.

What are burl and cluster veneers?

Burl and cluster veneers are rare and reserved for prestigious projects.

Burl veneer is composed of grouped pin-knots, which are densely packed and usually cover a good portion of the veneer sheet.

Cluster veneer, on the other hand, is characterized by the wild movement of its wood grain. However, clusters can also have pin-knots, either isolated or in clusters.

Numerous pin knots mean some pin knots are piercing, and open cracks are considered a natural part of this type of wood.

After gluing, you can fill the small holes with wood putty for a complete finish, or before gluing, cut out the larger holes with a cookie cutter and insert a veneer disc of the same size taken from a scrap.

By nature, burl or cluster veneer has a lot of end grain, so its sheets are often warped. Even when they have been pressed, they may still be slightly warped.

However, it is necessary to differentiate between two types of waving:

Hard waving makes a "pop" sound when you press on it with your finger.

In this case, it is advisable to flatten these veneers before using them. There are several methods; please inquire.

Soft waving, which does not make any noise.

In this case, there is no major problem; however, if you want to join several sheets together, it is better to press them beforehand.

What is American Walnut Wood?

What are the common Names for American Walnut Wood?

American Walnut, US Walnut, and Black Walnut.

What is the botanical name for American Walnut Wood?

Juglans Nigra.

According to Pliny the Elder, "Juglans" comes from "Jovis Glans," meaning "Jupiter's acorn."

Where can we find American walnuts in nature?

North America, Eastern United States, Eastern Canada.

However, it can also be found in Europe, particularly in France, where it has been planted in castle parks since the 15th century when it was in good taste to have tree species from the New World.

How to Recognize American Walnut Wood?

This wood is appreciated for its uniform structure and color; it is fairly dark brown with delicate black veins.

In its raw state (unvarnished), it is gray with purplish reflections, which gives way to a more or less dark brown once varnished or oiled.

With the patina of time, its brown color will give way to an orange honey. However, this orange honey can be obtained using a blond walnut (walnut sapwood) and a slightly orange-tinted finish.

It should be noted that American walnuts grown in France have less gray/purple and more brown color.

What are the mechanical properties of American Walnut Wood?

Weight: 610 Kg/m3, average at 10-12% humidity.

Janka Hardness: 4490 Newton. For comparison, Oak is 4980 N, and Poplar is 1650 N.

Modulus of Elasticity: 11.59 GigaPascal; for comparison: Ash 12.31 GPa and Poplar 9.75 GPa.

What are the uses of walnut veneers?

Walnut is used in furniture, decoration, car dashboards, guitar making, and old radios.

Several specialties are particularly sought, such as the burl, the root part of the trunk offering lively veining, or the burl, an outgrowth formed by hundreds of tiny knots.

What are Wood Veneers?

Veneers are thin sheets of wood obtained by slicing or peeling.

Their surface has the appearance of planed wood without any finish or treatment. They are neither glued nor backed with any other material. This means that both faces of the sheets can be used.

Wood Veneers are mainly used to cover less aesthetic substrates such as plywood or particleboard to make furniture or wall panels.

Veneers are also used to create decorative objects such as lamps, jewelry, bookmarks, and more.

By assembling several sheets of veneer on top of each other, it is possible to manufacture objects requiring high mechanical resistance, such as skis, bicycle frames, or musical instruments.

The applications of veneer are as varied as they are multiple.

Since veneers are genuine wood, all wood finishing products, whether varnish, stain, or oil, are suitable. The choice of finish will depend on your personal preferences and the final use of the object.

The veneer offered here is a sliced sheet of uniform thickness, but the thickness might differ from one species to another. The standard thickness is around 0.6 mm.

Although the edges of the veneers have been cut roughly straight, the cut is not perfectly parallel. Some veneers may retain the natural taper of the tree, being slightly wider at the foot than at the top.

Some veneers may have a trace of a wavy edge (an edge following the tree's natural shape) on the sides. In this case, the dimensions indicated correspond to the minimum width of the veneer, as specified in the "Dimensions" paragraph.

How to use veneers?

How to cut the veneers?

Veneers can be easily cut with a utility knife.

For straight cuts, the best results are obtained with a veneer saw.

Use a fretsaw, scalpel, or veneer knife for curved cuts.

Always allow for a slightly larger veneer sheet than your intended surface. This will allow you to adjust the size after gluing for a clean finish.

A flush trimmer can also be used to trim the veneer after gluing.

When cutting with a utility knife or veneer knife, it is best to cut with the grain of the wood. To check this, run your finger along the edge of the sheet. The direction that feels smoothest is the ideal direction for cutting.

What is veneer splicing?

As the veneers have the width that nature gave us, you might need to cover an area wider than the veneers available.

Therefore, you need to splice the veneers by gluing or fixing them side by side with tape to obtain the desired width.

Trim the veneer's edges with a straight and smooth cut to realize good jointing.

Stick the veneers with tape (the blue one is a good choice).

Usually, the veneers are spliced side by side, but to obtain a longer length, they can be done foot by foot.

The splicing must be done before gluing the veneers on the substrate.

What Glue to Use for Veneering?

Several types of gluing are possible.

Vinylic glue (PVA or PVB) is well adapted to porous substrates such as plywood, particle board, or MDF. The veneers must be pressed with clamps over the entire surface at once.

Note: A technique using vinyl glue and an iron can also be used to glue veneers, but we strongly recommend choosing this technique only if other gluing solutions are impossible.

- Neoprene glue is applied to all surfaces, especially non-porous surfaces, using two coats of glue and marouflage.

- Animal glue, such as hide, sinew, or bone glue, are pellets that must be cooked in a double boiler and used hot.

How to Sand Veneers?

Veneers and all our products are genuine wood and can be sanded according to thickness.

Please do not use a belt sander, regardless of the thickness of the veneer, as this could pierce it.

With a 0.6 mm veneer, lightly sand with 120 grit and then finish with 180 or 240 grit. With an orbital sander, 180 grit is already sufficient for most applications.

How to Finish a Veneer Realization?

All finishing products generally used for wood are suitable for finishing our products. For example, you can use a varnish, wax, paint, or oil.

However, ensure that the product you want to use is compatible with the final use of your creation.

More information:

Please look at our TUTORIALS; you might find some valuable tips.

Please contact us by email or phone for any additional information.

Data sheet

- Species

- Walnut

- Thickness group

- Standard

- Grade

- Burl

English

English