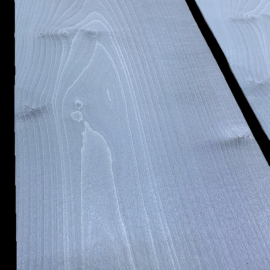

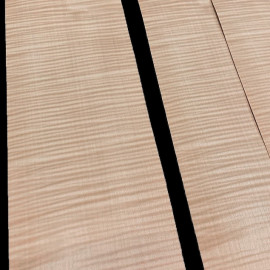

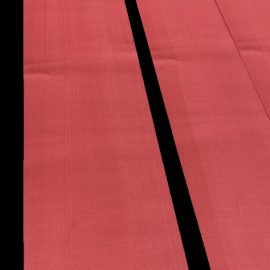

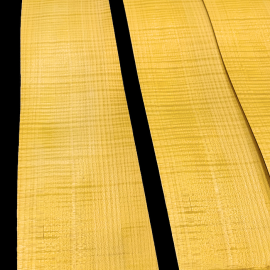

Dyed veneers

Veneers deep-dyed in bright colors

Genuine wood veneer sheets dyed down to the heart.

Deep-dyed veneers allow sanding after gluing to keep shiny colors.

Our veneers are not bleached before dying, so the wood keeps all its resistance and flexibility.

The most known creation with deep-dyed veneers is marqueterie, but it could be used for furniture, bow realization, and decoration.

English

English