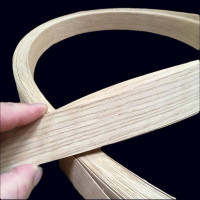

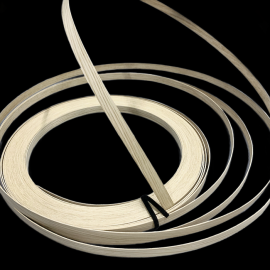

Oak edge band 35 mm

Oak edge band 35 mm

Genuine wood edge band.

These edge bands are sold by linear meters.

Width: 35 mm.

Thickness: 0.5 mm.

With fleece back and without glue or adhesive.

Oak edge band 35 mm

Genuine wood edge band.

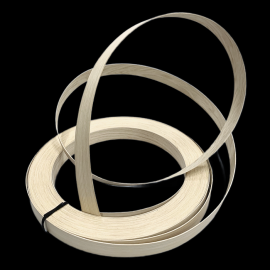

Sizes:

Fixed Width, parallel edges.

Length: 1 meter and multiples.

Width: 35 mm.

Thickness: 0.5 mm.

Quantities:

Sold in linear meters. Minimum order: 1 meter.

What are edge bands?

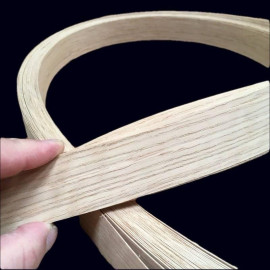

These edge bands are made of genuine wood.

They are pre-sanded, parallel cut, unglued, unvarnished.

Characteristics of edge band upon thickness are:

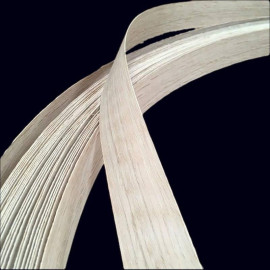

- 0.5 mm thick, backed with non-woven fabric.

- 1 mm thick, composed of 2 layers of wood veneer, glued wood to wood.

- 2 mm thick, composed of 4 layers of wood veneer, glued wood to wood.

Edge bands are supplied in a single roll of the length you choose.

The veneers used to make these edge bands are irregularly finger-jointed for a seamless appearance.

What are edge bands used for?

Edge bands are commonly used to cover the edges of veneered panels (plywood, MDF, particleboard, etc.).

Once the edge band is glued in place, the underlying substrate is no longer visible, revealing the appearance of the fine wood veneer on all sides.

Edge bands are also used for the restoration of furniture or interior woodwork.

Always plan for edge bands that are slightly wider than your target substrate. This will allow you to adjust the dimensions after gluing for a clean finish.

How to Glue Edge Bands?

Edge bands are glued in a similar way to wood veneers.

For porous substrates (MDF, plywood, particleboard, etc.), you can use either PVA wood glue or PU (Polyurethane, exterior wood glue). Apply the glue and clamp the edge bands in place using a rigid caul and a sufficient number of clamps.

Alternatively, you can use a contact glue like neoprene. This glue is recommended for non-porous substrates such as metal, plastic, or glass but also works on porous substrates.

Double gluing is necessary with contact glue. Allow the glue to dry to the touch before contacting the surfaces.

Then, gradually mount the edge band into place using the hand.

A second strong mounting is essential, with a wooden caul or a veneer hammer. This last step is crucial and should not be neglected. Neoprene glue also allows you to cover curved pieces.

Note:

There are many other methods for gluing veneers, such as vacuum pressing or animal glue (bone glue, hide glue). Still, the methods mentioned above are the most common without requiring specialized equipment.

However, there is a third method that might be useful to know:

Iron-On Gluing Method

This method exclusively applies to edge bands between 0.5 mm and 1 mm in thickness. For thicker edge bands, the heat from the iron might not penetrate the wood correctly.

This gluing method requires a porous substrate and PVA wood glue (either fast-drying or standard drying).

Using a brush or roller, apply a thin, even coat of glue to the edge band and the substrate. Ideally, a rubber brayer would be used, but a paint roller can also be used, but it may consume more glue. Ensure that any excess glue is removed with a spatula or plastic card.

Allow the glue to dry until it is touch-dry. The drying time will vary depending on the glue and room temperature. You can speed up the drying process by using a hairdryer.

It's time to apply the edge band when the glue no longer sticks to your fingers and has become transparent in some areas while still milky in others.

Position the edge band on the substrate. Since this is not a contact glue like neoprene, use tape to hold it in place.

Press the iron firmly over the edge band using a cotton setting with no steam.

Take your time to allow the heat to penetrate the wood.

The wood is unlikely to burn from the iron (unless you leave the iron on the wood for an extended period), but if you're using your everyday iron, protect the soleplate with baking paper, as wood is abrasive.

Once the glue has set, trim off any excess edging.

How to Trim Edge Bands?

Several techniques can be used:

With a veneer saw: It is the best solution if your workpiece is straight and can be positioned on its edge.

With a wood chisel: Place the chisel at an angle (don't attack the band head-on) and apply a movement from the outside to the inside, gradually advancing in small up-and-down motions.

With a utility knife or veneer knife: Identify the wood grain before cutting. Run your finger along the edge of the band in one direction and then the other. Cut in the direction that catches the least.

With an electric trimmer: For those who have one, remember to stop a little before the end of your piece and finish the last centimeter with a chisel or utility knife.

Note: Edge band trimmers sold in DIY stores are designed for plastic edge banding. If you want to use this tool, sharpen it as much as possible and, as with the utility knife, respect the direction of the wood grain.

The final step is to finish your piece.

What finish for an edge band?

As you probably read in the introduction, our edge bands are pre-sanded. For finer sanding, use a minimum of 180 grit.

Since our edge bands are wood, any wood finish product is suitable.

Just ensure the chosen product is compatible with the final use of your project.

You now know almost everything! I recommend this excellent video tutorial by Le Bois Barbu.

What is This French Oakwood?

Considered in France as the noblest wood par excellence, it is the sacred tree of the Druids and also the tree under which Saint Louis dispensed justice.

It is particularly prevalent in state forests, the organization and silviculture of which are due to Colbert, the minister of Louis XIV. Therefore, Colbert desired a powerful navy and numerous, well-organized oak forests for sustainable renewal. However, Colbert could not foresee that 250 years later, when the trees were old enough, warships would no longer be made of wood.

Oak is a very tannic wood, hence the Gaulish name for oak, "tann," which gave rise to the words tanner, tanner, tannin, etc. Oak tannin has been used since antiquity to tan hides. It is also what develops woody flavors in wine and deepens its red color.

What are the common Names for this Oakwood?

Oak, European white Oak, Common Oak, Pedunculate Oak.

What is the botanical name for this Oakwood?

Quercus petraea and Quercus robur.

Where can we find European Oak in nature?

Generally, oak can be found throughout the Northern Hemisphere.

In France, the common oak and the pedunculate oak are the main species in the northern French oak forests. Sessile oak is more rarely found, but this remains anecdotal.

In southern France, the evergreen oak and the cork oak are emblematic.

How to Recognize European Oak Wood?

Oak is a wood with a hard texture and large pores. It is recognizable by its fine and discreet grain on the flat-sawn surface, but it is more present, even omnipresent, on the quarter-sawn surface.

Its raw color is generally a sandy blonde. However, it varies depending on the soil (siliceous or calcareous) and the type of plantation (high forest or coppice).

Among the different appearances of oak, the most iconic are:

Brown oak: Generally, brown is an upward coloration of the base of the oak when the tree becomes old, a bit like human hair that turns gray/white. Like some humans, certain trees become completely brown, sometimes even in early adulthood, except for the sapwood, which remains white.

Smoked oak: This is an oak whose tannin has been reacted to give it a color ranging from milky coffee brown to charcoal black.

Swamp oak: These are oaks that fell into a swamp several thousand years ago. They are generally discovered during agricultural earthworks.

These oaks are in the process of fossilization. They have a very particular charcoal gray hue, and of course, they are rare.

Flaky oak: The flake is the oak's medullary rays, in other words, its "skeleton." When you cut a plank or a veneer on the quarter, you find yourself parallel to the medullary rays, and as a result, the flake is noticeable and creates unique aesthetic patterns.

Other specialties are oak burl, oak crotch, and knoty oak... will complete this non-exhaustive list.

What are the mechanical properties of European Oak?

Weight: approximately 675 kg/m³ at 10-12% moisture content

Janka hardness: 4980 Newtons; for comparison, ash is 6580 N, and poplar is 1650 N

Elasticity: 10.60 Gigapascals; for comparison, US maple is 12.62 GPa, and poplar is 9.75 GPa.

Tensile strength: 97 Megapascals; for comparison, US maple is 109 MPa, and poplar is 62 MPa.

What are the uses of Oak veneers?

Oak is a wood that combines strengths, like a decathlon athlete who is not the best in any discipline but is strong in several.

Thanks to its qualities, oak is used in many areas:

Construction: Oak is used to construct frames, floors, exterior joinery (doors, windows), and decorative elements (paneling, moldings).

Furniture: Oak is a highly prized wood used for manufacturing quality furniture such as tables, chairs, wardrobes, and chests of drawers.

Flooring: Oak flooring is very resistant and aesthetic. It is often chosen for quality floors.

Cooperage: Oak is used to make aging barrels for wines and spirits.

Other uses: Oak is used to manufacture tools, decorative objects, and boats.

More info:

Should you need more info, please get in touch with us either by email or by telephone.

Please look at our TUTORIALS, and you might find some valuable tips.

You might also like

English

English