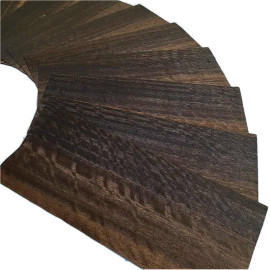

Eucalyptus XXL Small-size Veneers

Eucalyptus XXL Small-size Veneers

Genuine wood veneer sheets.

Selected single veneers, no sequence.

Length: 30 cm (approximately 12 inches).

Width: 22 to 36 cm (approximately 8 to 14 inches), depending on availability.

Thickness: 0.6 mm (approximately 1/40 inches).

Sold by the sheet.

Please read the description of these veneers.

Eucalyptus XXL Small-size Veneers

Genuine wood sliced-veneer sheets.

Selected single veneers, no sequence.

Dimensions:

Length: 30 cm (approximately 12 inches).

Width: 22 to 36 cm (approximately 8 to 14 inches), depending on availability.

Thickness: 0.6 mm (approximately 1/40 inches).

Measurement scaling:

The width is rounded to the covered centimeter, for example, 15.8 cm, giving 15 cm.

Photos:

To keep the cost of these products as low as possible, unlike other veneers on this website, the pictures of small-size veneers do not represent the actual stock available.

What are Small-size Veneers?

These are veneer sheets with a fixed length of 30 cm (exactly 30.5 cm).

These sheets are not in a continuous sequence and may come from different logs.

What is Eucalyptus?

What are the common names for eucalyptus?

Eucalyptus, Gommier, Lyptus®.

What is the botanical name for eucalyptus?

Eucalyptus urograndis (Eucalyptus grandis x urophylla hybrid).

What is the origin of eucalyptus?

Eucalyptus is originally an Australian wood. It has been introduced to North and South America, North Africa, and Europe, particularly in Portugal, where entire forests can be found.

This specific type of eucalyptus is a Brazilian plantation wood, sold in solid form under the name Lyptus®. It's a hybrid created to replace Swietenia mahogany, which is now banned from commercial use.

It's an ultra-fast-growing hardwood: it takes only 15 years to reach a sawable diameter and 18 years to reach a sliceable diameter. For comparison, an oak tree is ideally harvested after 150 to 180 years.

How can you identify eucalyptus?

Generally, eucalyptus is a yellowish wood that can have brown or green veins.

In the case of Lyptus®, its color varies from one log to another, ranging from a pink similar to Okoumé to a brownish-orange reminiscent of mahogany.

Despite being a fast-growing tree, certain varieties of it are hard or even very hard wood.

Eucalyptus can have a moiré effect, offering more or less regular reflections; it can also be figured, with very distinct and particularly aesthetic reflections.

What are the mechanical properties of eucalyptus?

Weight: approximately 850 kg/m³ at 10-12% moisture

Janka hardness: 6330 Newtons. For comparison, ash is 6580 N and poplar is 1650 N.

Elasticity: 14.13 Gigapascals. For comparison, US maple is 12.62 GPa, and poplar is 9.75 GPa.

Breaking stress: 118 MPa. For comparison, US maple is 109 MPa, and poplar is 62 MPa.

What are the uses of eucalyptus?

Eucalyptus is used for flooring, interior joinery, furniture making, decoration, and the production of plywood.

What are wood veneers?

Veneers are thin sheets of wood obtained by slicing or peeling.

Their surface has the appearance of planed wood without any finish or treatment. They are neither glued nor backed with any other material. This means that both sides of the sheets can be used.

Veneers are mainly used to cover less aesthetically pleasing substrates, such as plywood or particleboard, to create furniture or wall panels.

Wood veneers are also used to create decorative objects, including lamps, jewelry, bookmarks, and more.

By assembling several sheets of veneer on top of each other, it is possible to manufacture objects requiring high mechanical resistance, such as skis, bicycle frames, or musical instruments.

The applications of veneer are as varied as they are multiple.

Since veneers are genuine wood, all wood finishing products, including varnish, stain, and oil, are suitable. The choice of finish will depend on your personal preferences and the object's intended use.

The veneer offered here is a sliced sheet of uniform thickness; however, the thickness may vary from one species to another. The standard thickness is around 0.6 mm.

Although the edges of the veneers have been cut roughly straight, they are not perfectly parallel to each other. Some veneers may retain the natural taper of the tree, being slightly wider at the foot than at the top.

Some veneers may have a slightly wavy edge on the sides, one that follows the natural shape of the tree. In this case, the indicated dimensions correspond to the minimum width of the veneer, as specified in the "Dimensions" paragraph.

How to use veneers?

How to cut the veneers?

Veneers can be easily cut with a utility knife.

For straight cuts, the best results are obtained with a veneer saw.

Use a fretsaw, scalpel, or veneer knife for curved cuts.

Always allow for a slightly larger veneer sheet than your intended surface. This will allow you to adjust the size after gluing for a clean finish.

A flush trimmer can also be used to trim the veneer after it has been glued.

When cutting with a utility knife or a veneer knife, it's best to cut with the grain of the wood. To check this, run your finger along the edge of the sheet. The direction that feels smoothest is the ideal direction for cutting.

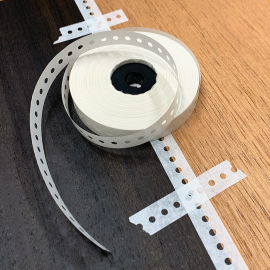

What is veneer splicing?

Since veneers come in the width that nature gave us, you may need to cover an area wider than the available veneers.

Therefore, you need to splice the veneers by gluing or fixing them side by side with tape to obtain the desired width.

Trim the veneer's edges with a straight, smooth cut to achieve a good joint.

Stick the veneers in place with tape (the blue one is a good choice).

Usually, the veneers are spliced side by side, but they can be spliced butt-match to obtain a longer length.

The splicing must be done before gluing the veneers on the substrate.

What Glue to Use for Veneering?

Several types of gluing are possible.

Vinylic glue (PVA or PVB) is well-suited for porous substrates such as plywood, particleboard, or MDF. The veneers must be pressed with clamps over the entire surface at once.

Note: A technique using vinylic glue and an iron can also be used to glue veneers; however, we strongly recommend using this technique only if other gluing solutions are not feasible.

- Neoprene glue is applied to all surfaces, especially non-porous surfaces, using two coats of glue and marouflage.

- Animal glue, such as hide, sinew, or bone glue, is a product that must be cooked in a double boiler and used hot.

How to Sand Veneers?

Veneers and all our products are made from genuine wood and can be sanded according to the thickness of the veneer.

Please do not use a belt sander, regardless of the veneer's thickness, as this could pierce it.

With a 0.6 mm veneer, lightly sand with 120-grit sandpaper and then finish with 180- or 240-grit sandpaper. With an orbital sander, 180-grit is already sufficient for most applications.

How to Finish a Veneer Realization?

All finishing products generally used for wood are suitable for finishing our products. For example, you can use a varnish, wax, paint, or oil.

However, ensure that the product you want to use is compatible with the final use of your creation.

More information:

Please review our tutorials; you may find some valuable tips.

Please don't hesitate to contact us by email or phone for any further information.

Data sheet

- Species

- Eucalyptus

- Thickness group

- Standard

- Width group

- XXL width

You might also like

English

English