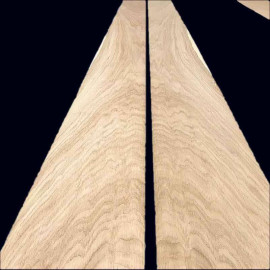

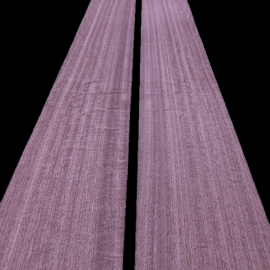

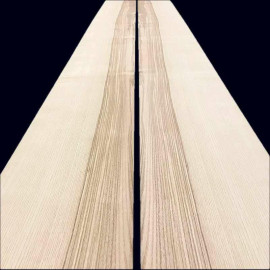

Long Veneers

Genuine wood veneer sheets, long length.

Length 180 cm and longer.

Various species are available: from the classic Oak, Ash, Cherry, and Beech to the precious Ebony and Rosewood.

These veneers are sliced mainly in 0.6 / 0.5 mm thicknesses and some particular thicknesses of 0.3 mm.

Other specialties such:

- Fiddled and figured Sycamore.

- Fumed Oak, Beech, and Eucalyptus.

- Pommele and Bird's Eye Maple.

English

English