Burls & Crotches

Veneer Burls and Veneer Crotches

These are special wood-sliced veneer sheets of burls, swirls, and crotches for joinery, marqueterie, car dashboard, and instrument making.

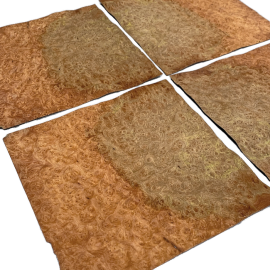

Burls:

This natural singularity is composed of hundreds of tiny knots, which gives the wood a rare character. Every burl design is unique.

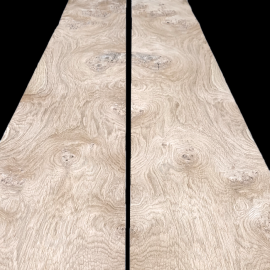

Crotches:

Crotch veneers come from the log part, where two branches grow apart. Crotches are very appreciated for joinery and instrument-making.

Swirls:

Swirls are veneers with many savage patterns, They may have a few knots or pin-knots, but the most specific pattern is the structure movement.

English

English