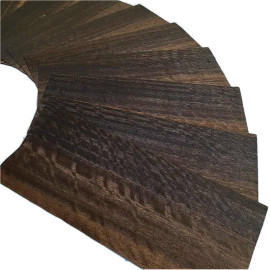

Small sizes veneer

Small-size genuine wood veneers.

These are genuine wood veneers with a fixed length of 30 cm.

Widths are the one nature given us:

From 8 to 13 cm for the narrow ones.

From 14 to 21 for standard widths.

Tag XXL for 22 cm and broader veneers.

Thicknesses are from 0.3 mm to 3 mm.

Please use the filters on the left side of your screen to find your small-size veneers upon more than one hundred references.

English

English